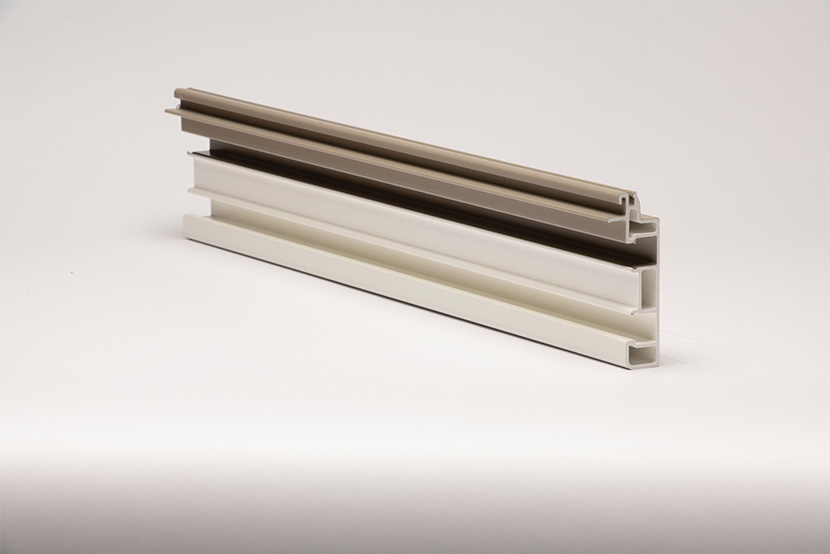

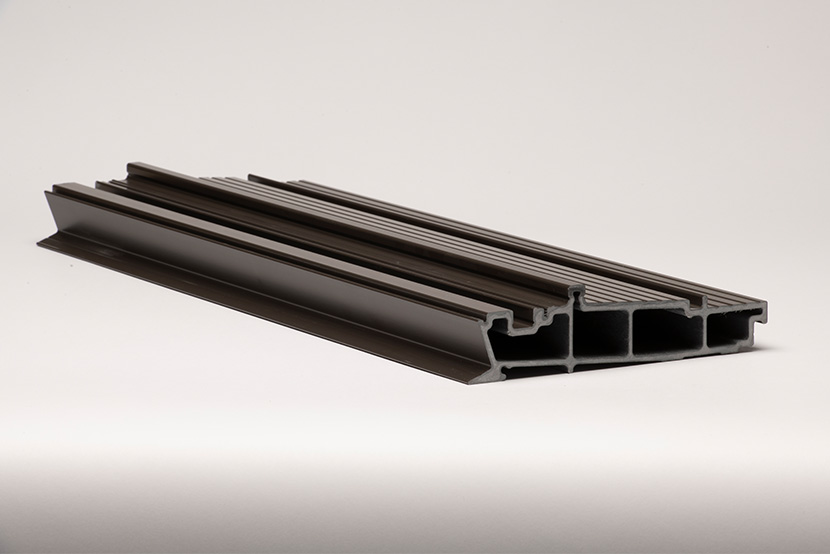

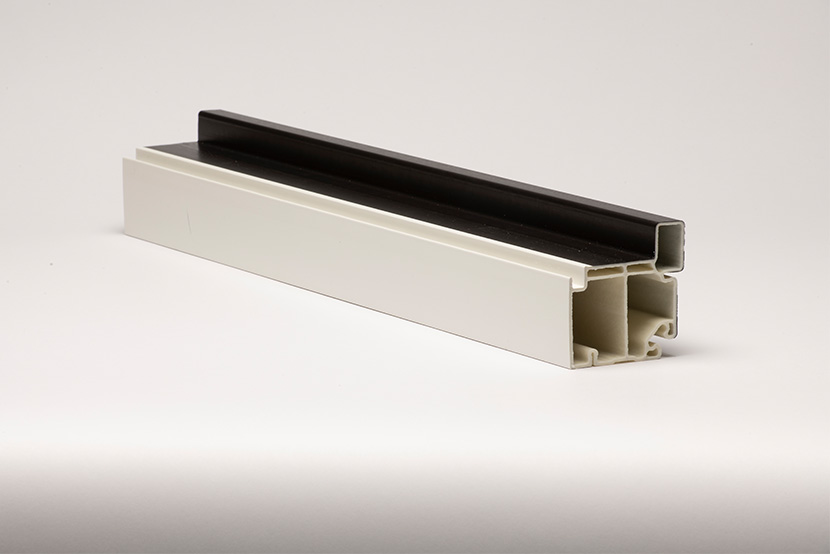

Marvin Composites partners with large manufacturers to make products better. We design, engineer, and manufacture custom pultruded and extruded fiberglass components.

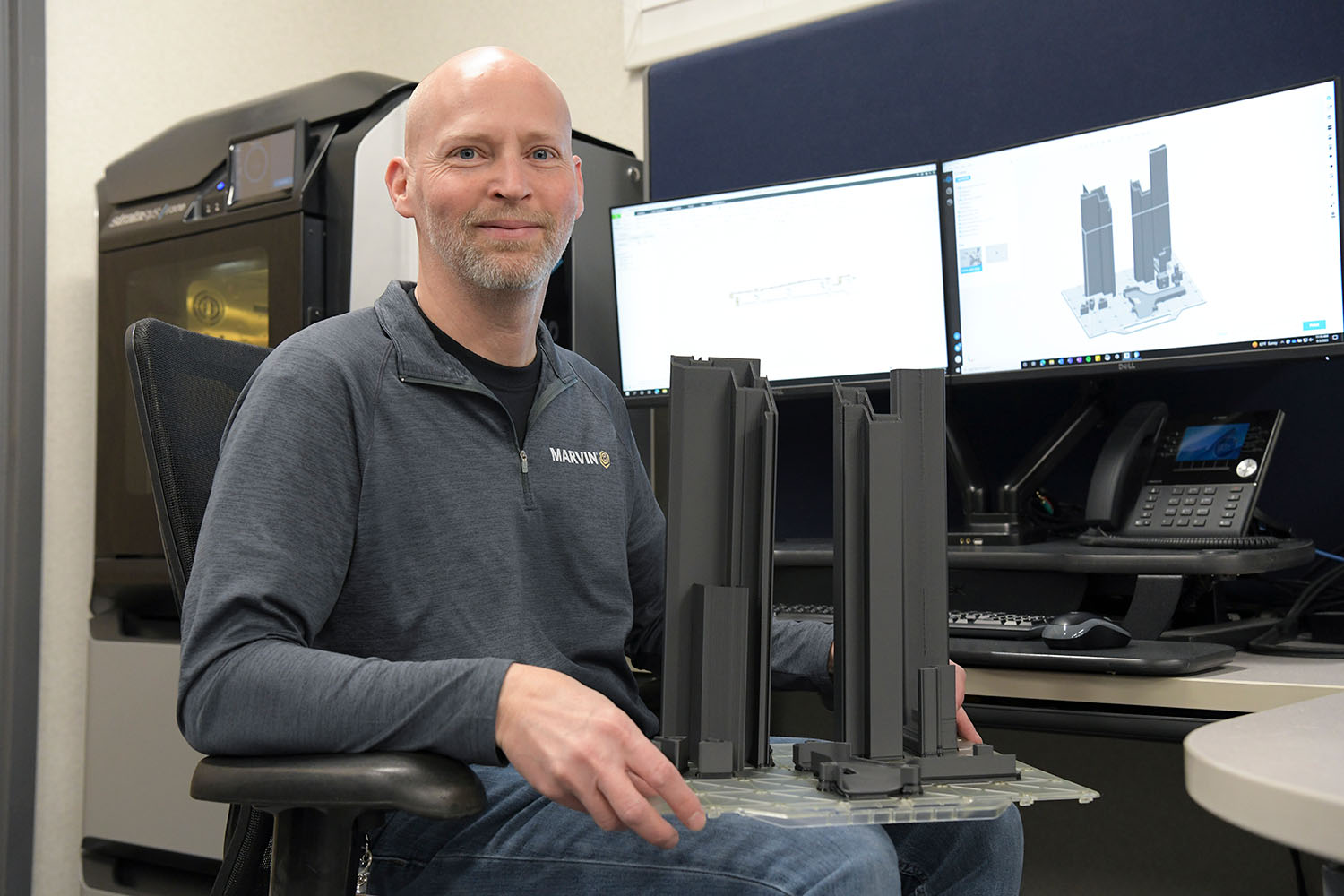

Inspired by Possibilities

We are constantly challenging ourselves and encouraging new ideas and innovations to remain on the leading edge of fiberglass reinforced material advancements.